News Center

Shandong Zhensure New Materials Technology Industry Co., Ltd.

Artificial grass has become a premier choice for a multitude of applications, from expansive sports fields and football pitches to residential lawns and commercial landscaping. For importers, distributors, and wholesalers, providing clients with high-quality, long-lasting synthetic turf is paramount for customer satisfaction and repeat business. Understanding the key factors that contribute to the longevity of artificial turf is essential for making informed sourcing decisions. This guide outlines crucial strategies to maximize the durability and performance of artificial grass installations.

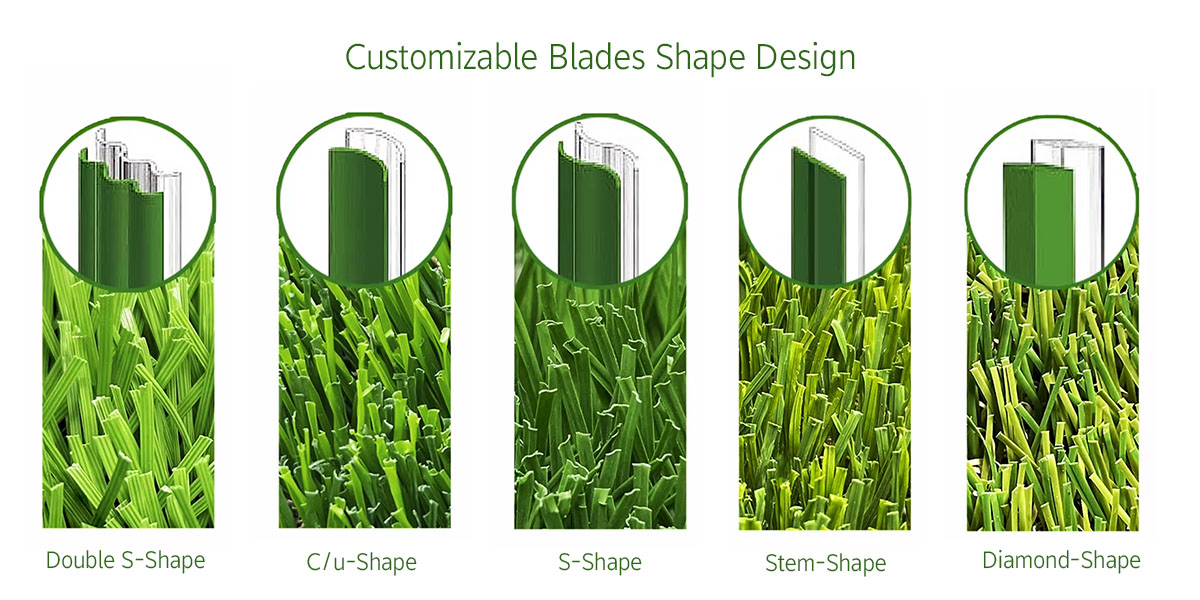

The inherent durability of any artificial lawn is fundamentally determined by the quality of its core components: the grass blades (yarn) and the backing system. Key specifications to evaluate include stitch density (the number of stitches per square meter), denier (the weight of 10,000 meters of yarn, indicating blade thickness and strength), and pile height. Generally, a higher denier and denser stitch count correlate with a more robust and resilient product. The backing material is equally critical; premium options often feature a multi-layered construction, sometimes reinforced with a secondary mesh cloth. This design significantly enhances dimensional stability and prevents the backing from stretching or fracturing over time.

The selection phase is the first critical step. Opting for the lowest-priced product can be a costly mistake, as some manufacturers may compromise on material quality—using inferior yarn formulas or thinner backing—to cut costs. Partnering with a reputable manufacturer like Zhensure Xinke, known for its commitment to quality and reliability, ensures the product itself is engineered for long-term durability. Beyond the product, professional installation is a non-negotiable factor. Experienced installation teams, often affiliated with quality factories, use precise methods and equipment to ensure a perfectly even and stable sub-base, which is the foundation for a long-lasting surface.

Proper infill selection and application are also vital. High-quality, rounded silica sand or environmentally friendly rubber granules should be used. These materials cushion the blades, help them stand upright, and provide necessary shock absorption. Sharp or dirty infill materials can cause premature wear and damage to the yarn. Furthermore, educating end-users on basic maintenance is a value-added service you can provide. Recommendations include regular brushing to lift the fibers, promptly removing debris like leaves, avoiding open flames, and conducting semi-annual inspections to check for loose seams or infill displacement.

By focusing on premium materials, expert installation, and simple maintenance, the functional lifespan of artificial grass can be significantly extended, ensuring superior performance and aesthetic appeal for years to come. This commitment to quality ultimately protects your investment and strengthens your reputation in the market.

Installing WPC decking is renowned for its simplicity compared to traditional materials like ceramic tiles, offering significant time and cost savings.

Discovering that the edges of your artificial grass are lifting or peeling up can be a frustrating sight for any property owner or field manager.

When selecting WPC (Wood Plastic Composite) decking for a project, buyers are often faced with a fundamental choice right from the start

When selecting high-quality Artificial Grass, buyers often focus on the manufacturer’s reputation, product durability, and cost.

Artificial grass has become a premier choice for a multitude of applications, from expansive sports fields and football pitches to residential lawns and commercial landscaping.