News Center

Shandong Zhensure New Materials Technology Industry Co., Ltd.

For professional installers and distributors of WPC decking, understanding the technical nuances of installation is as important as the material quality itself. One fundamental principle that cannot be overlooked is the incorporation of expansion gaps. These deliberate spaces between decking boards are not an aesthetic compromise but a critical engineering requirement for ensuring the long-term performance and durability of any outdoor deck. This article explains why these gaps are essential and how they contribute to the superior performance of WPC decking systems in diverse climatic conditions.

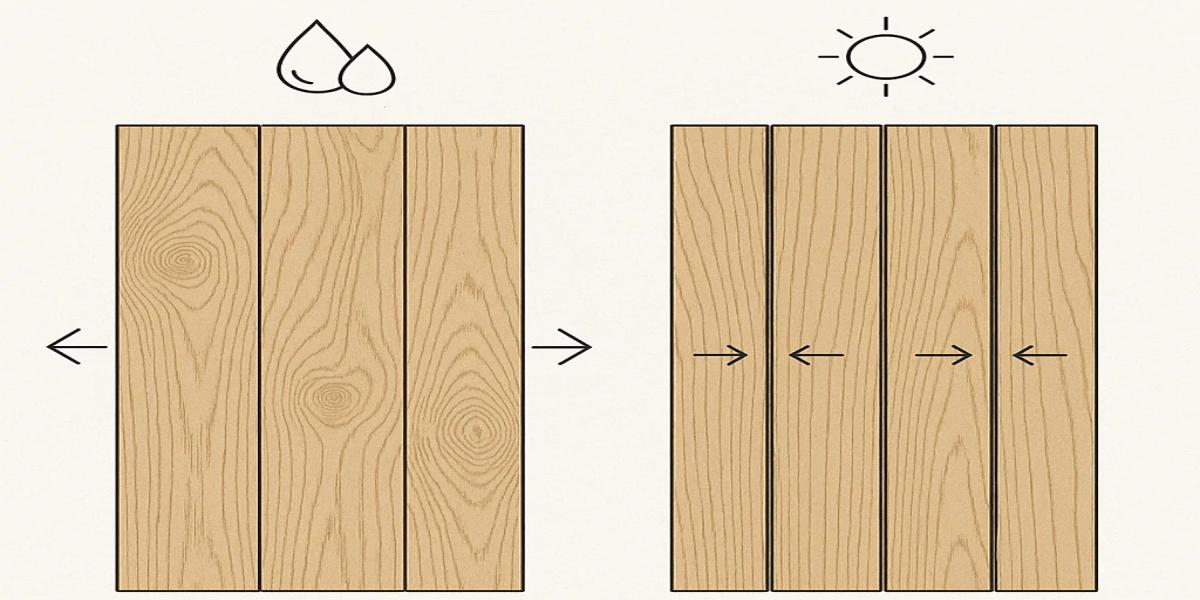

1. Accommodating Natural Thermal Expansion

All building materials, including Wood-Plastic Composites, react to environmental changes. As temperatures fluctuate, WPC boards naturally expand and contract. Without adequate space at the ends and between boards, this movement creates tremendous pressure, leading to unsightly and hazardous buckling, warping, or lifting of the entire deck structure. A properly planned gap acts as a relief valve, allowing the material to move freely without causing damage, thus preserving the structural integrity and smooth surface of the installation.

2. Ensuring Optimal Ventilation and Drainage

An outdoor deck is constantly exposed to rain and moisture. Standing water is one of the biggest threats to any outdoor structure. Strategic gaps between WPC boards facilitate rapid water runoff and promote crucial air circulation beneath the deck surface. This "breathing" effect allows moisture to evaporate quickly, preventing the accumulation that can lead to mold, mildew, or a slippery surface. For installers, this means that a properly installed WPC deck will have superior drainage, directly contributing to its longevity and reducing moisture-related callbacks.

3. Protecting the Substructure and Joists

The decking surface is only as healthy as the substructure that supports it. Whether using traditional timber joists or modern aluminum systems, this underlying framework must be protected from trapped moisture. Tightly butted boards create a sealed environment where water becomes trapped, accelerating the decay of wooden joists or promoting corrosion in metal frames. Consistent gapping ensures that the substructure remains dry and well-ventilated, significantly extending the lifespan of the entire deck assembly, from the visible surface to the hidden support system.

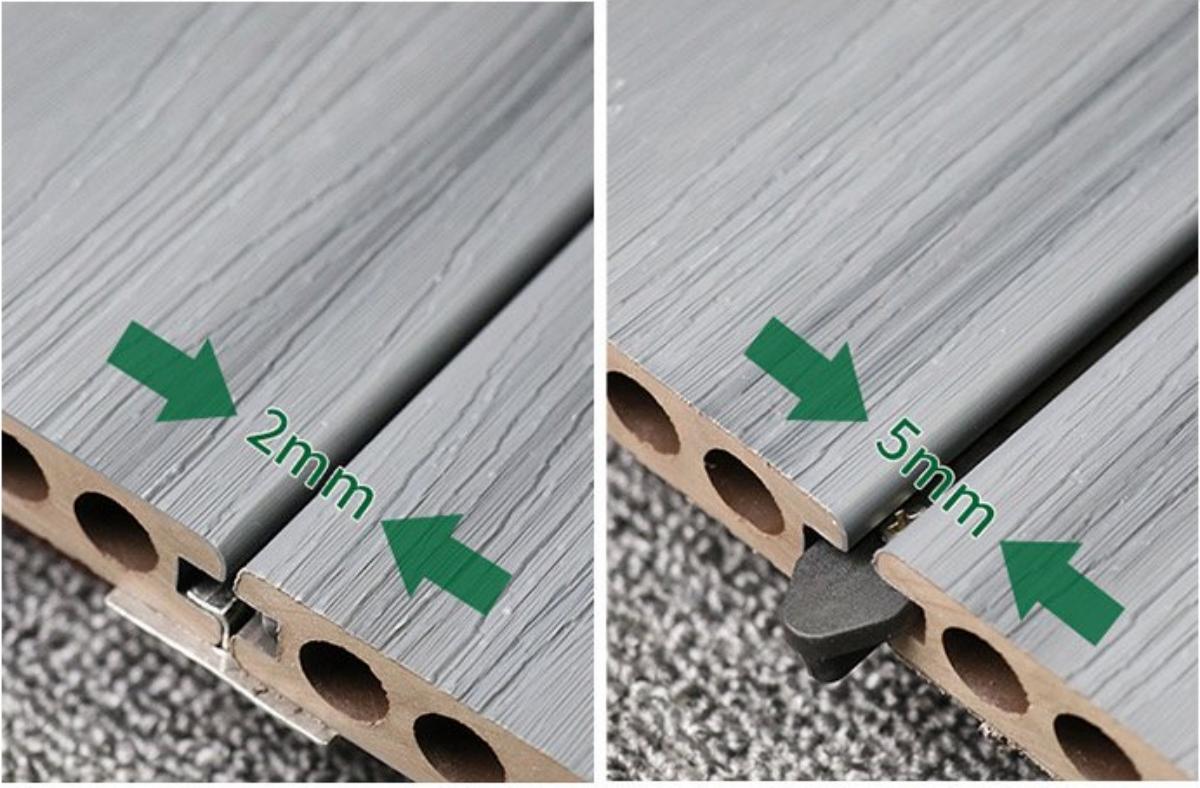

Determining the Correct Gap Size

The ideal gap width is not arbitrary; it is calculated based on several factors:

Board Length: Longer board runs require larger expansion gaps at their terminals.

Installation Temperature: Installation during colder weather requires smaller initial gaps than installation in peak heat.

Local Climate: Regions with high temperature variations between seasons necessitate more significant gaps.

Contrary to common concerns, these gaps do not negatively impact the user experience. Debris that falls through can be easily washed away, and modern WPC decking profiles are designed so that the gaps are functional without being visually intrusive or uncomfortable underfoot.

In conclusion, the correct implementation of expansion gaps is a non-negotiable best practice that safeguards your investment in outdoor living spaces. It is a simple yet powerful technique that prevents costly future repairs and ensures customer satisfaction. At Zhensure, we provide comprehensive installation guidelines with our products, empowering our partners to deliver flawless and enduring WPC decking projects that stand the test of time and nature.

For professional installers and distributors of WPC decking, understanding the technical nuances of installation is as important as the material quality itself.

Transforming underutilized rooftops into functional and beautiful spaces is a growing trend in urban design, and artificial grass has emerged as a key component in these projects.

Modern homeowners are increasingly investing in their outdoor living spaces, leading to a surge in demand for high-quality patio and garden flooring.

The global Artificial Grass market has reached a mature stage, offering a vast array of options for landscapes and sports fields.

As wood resources become increasingly scarce and environmental protection requirements grow higher, wood-plastic composite (WPC) materials—made from recycled wood flour and straw—are gaining more and more attention.